Extraction hood

Extraction hood

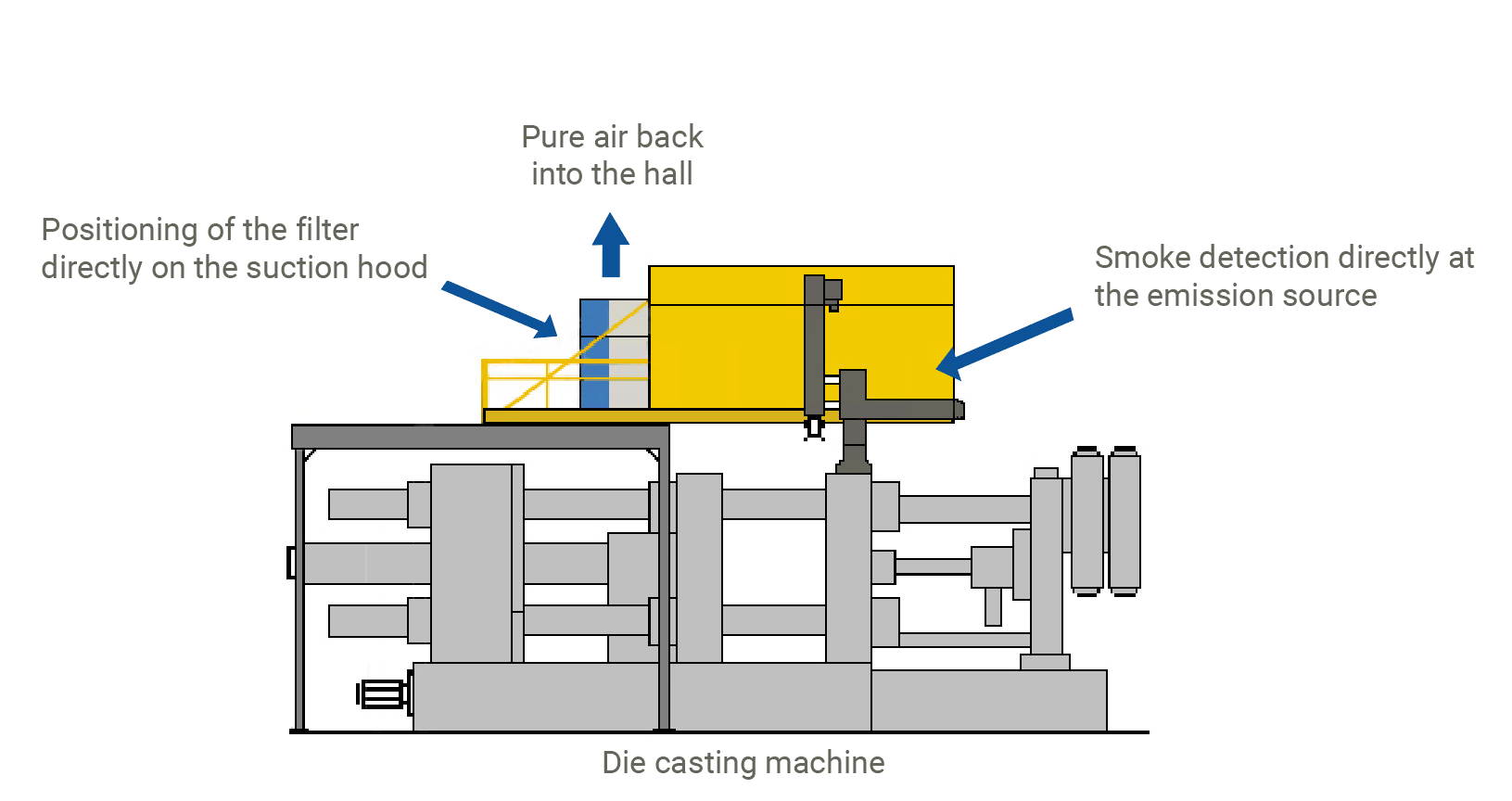

An extraction hood, also called smoke extraction hood, is an appliance mounted above the emission source of contaminated production exhaust air. The extraction hood contains the contaminated exhaust air preventing it from spreading in the production hall. After being contained by the extraction hood, the production exhaust air is then transferred to the electrostatic precipitator module to be purified.

The exhaust air generated in foundries is made up of oily smoke and aerosol substances. Continuous use of the machines creates smoke that has to be separated.

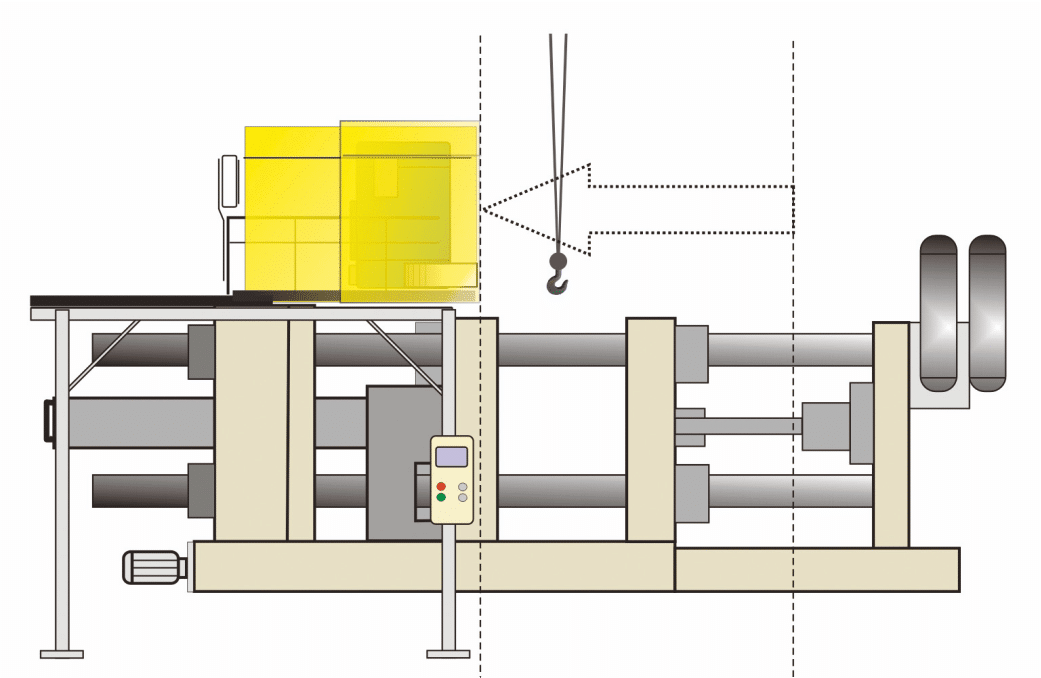

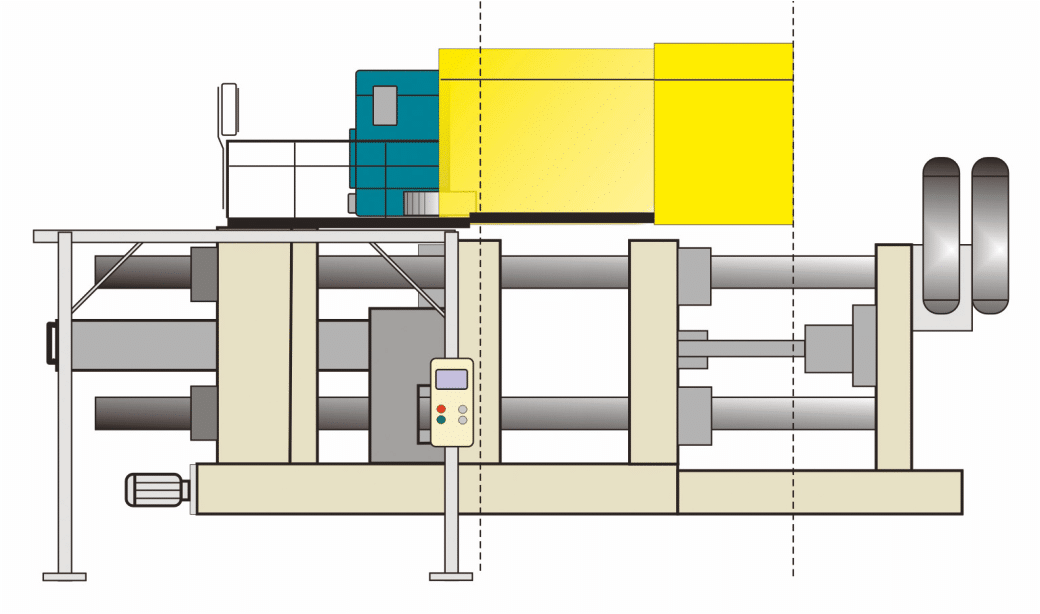

ULTRAVENT® extraction hoods are available in one- or multi-part models: as one- and two-part hood or as telescopic hood. If required, the regular or space-saving telescopic hoods can be moved aside, sliding on rails. The hood can be moved either manually or by using a hood motor drive. This ensures an entirely free crane access for die change or servicing of the die machine at any time.

Due to the special design inside the hood (built-in deflector plates) even strong and intermittent smoke emissions can be efficiently extracted and removed from the exhaust air stream. Flow baffle plates ensure that the suction effect is focusing on the emission-critical areas of the hood’s bottom edges.

In production plants where KMA smoke detection hoods cannot be installed due to lack of space, KMA Umwelttechnik relies on its efficient air curtain systems to enclose contaminated exhaust air.

Smoke detection hood, opened for free access

Smoke detection hood, closed and in working condition

Related links

Related posts