Air filtration & heat recovery for textile finishing

As leading solution provider KMA offers energy efficient exhaust air filter system for the textile industry. The application of an KMA exhaust air filter system is pursuing two goals: Clean air in the textile industry and the reduction of energy consumption through heat recovery. Depending on the textile finishing process, different pollutant emissions arise at the stenter frame and need to be treated. In addition to fumes, oil smoke and aerosols, also wax particles, formaldehyde, synthetic resins or fluorocarbon resins have to be separated from the contaminated exhaust air. KMA exhaust air filters specialize in these complex requirements of exhaust air purification and are designed for the following processes in textile finishing:

Heat treatment

- Thermosetting

- Raw material thermofixation

- Easy care equipment finishing

Wet finishing

- Fluorocarbon finishing

- Flame-retardant finish

- Silicone finishing

- Synthetic dispersion

Coating

- PVC coating

- Nonwoven coating

- Foam coating

Less energy consumption means less costs!

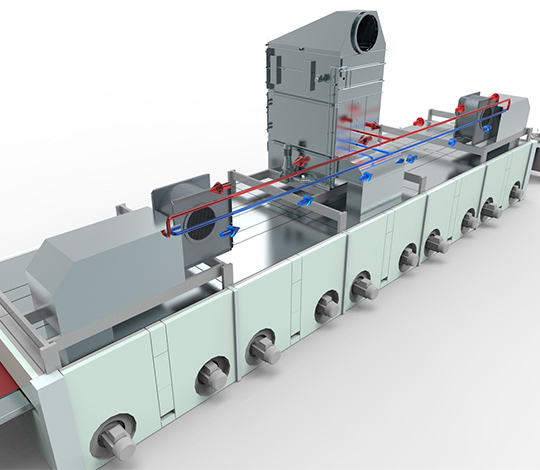

The exhaust air from stenter frame systems consist to a considerable extent of dust and oily aerosols but also of a valuable amount of heat from production processes. Even the separation of wax particles in textile finishing need to be concidered. Nowadays, the textile industry is confronted with strict regulations in terms of occupational health and safety as well as environmental protection. KMA ULTRAVENT® exhaust air filter systems accommodate these requirements already: they are suitable for separation of oily, greasy or pasty aerosols from the exhaust air and are characterised by high separation efficiency, durability and very low energy consumption. Due to the integrated heat recovery technology, the textile manufactory can also handle ambitious goals for improving its carbon footprint and put high amounts of energy savings into practice. Depending on the mixture of exhaust air the ULTRAVENT® electrostatic filter cells can be combined with additional filters as UV light tubes, activated carbon or gas scrubber . The oil contained in the exhaust air is separated and discharged via a drainage opening.

Cost reduction potential

We would be glad to provide you with an analysis free of charge.

The advantages at a glance!

The advantages at a glance!

No matter if you cast, press, drill or mill: With KMA ULTRAVENT® you master every exhaust air problem and remain free in the choice of the production process.

KMA exhaust air filtration systems do not have a negative influence on the process in the production plant. Existing production plants can continue to be used without modification and, after connection to a KMA exhaust air filter system, meet the requirements of the Federal Immission Control Act (BImSchG).

KMA exhaust air filter plants use the combined process of electrostatic precipitator and other modular elements (e.g. heat exchanger and UV light for odour separation), the most modern and economical method for exhaust air purification. Compared to conventional exhaust air purification systems, up to 80 percent of energy costs are saved.

KMA exhaust air filtration systems ensure compliance with the emission limit values according to the TA-Luft* regulations and the VDI** directives. KMA systems are designed according to the high requirements of the German legislation relating to workplace safety (BG) and Federal Imission Control Act (BlmSchG).

KMA exhaust air filtration systems are not vulnerable to thermal wear. More than 3,000 systems installed in numerous manufacturing works – some with over 50,000 hours of operation – prove this in a striking manner.

The convenient automatic filter cleaning system cleans the modules in regular intervals, which ensures the durability of the filter modules and low maintenance operation.