Air filter systems for the metal industry

Clean air. Save energy.

KMA produces exhaust air filtration systems for many application areas in the metal processing industry. The development focus of our engineers and process technicians has always been sustainability and efficiency. The result: KMA exhaust air filtration systems usually need about 80 % less energy than traditional air filtration systems in the metal processing industry!

Less energy consumption means less costs!

High separation efficiency of smoke and fumes.

Your expert for energy saving exhaust air filtration:

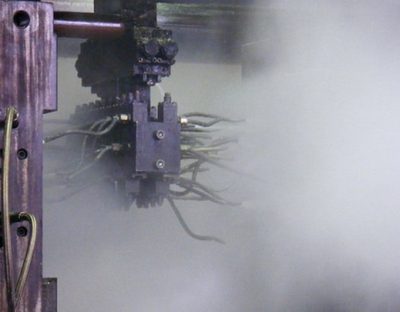

Clean air in foundries

KMA Umwelttechnik stands for quality and innovation. This is proven every day by more than 3.000 air filter systems installed world-wide. Their application allows the prevention of environmental pollution and makes an important contribution to the climate protection.

Application areas of the energy-efficient KMA exhaust air filtration systems in the metal industry:

- Foundries

- Presses, Forges

- Processing machines

- Extruders

- Reflow processes, Soldering

- Welding machines and robots

- Laser cutting machines

Active environmental protection, that pays off

KMA filter systems clean exhaust air highly efficiently and save energy and money

In the energy-intensive production processes of the metal industry often exists considerable savings potentials, which can have significant effects on the competitiveness of the company. Besides the energy consumption for the manufacturing process of the metal the one for exhaust and supply air systems is very important. The high energy consumption goes hand in hand with the corresponding emission of CO2.

KMA delivers the energy-efficient solution:

KMA offers with the ULTRAVENT exhaust air filtration system an energy-efficient solution for the waste air treatment. Given an extremely high collection performance by the filter, the energy cost will be reduced and thus the emissions of CO2. Environmental compatibility and economic efficiency are no opposites for the KMA Filter Systems, but ideally complement each other and even reinforce one another.

”Care for clean air at the workplace and save real money at the same time ”

Ask KMA for a free comparative calculation of operating costs for your application. KMA exhaust air filtration systems ensure clean air and thus reduce your natural gas consumption!

Save energy, conserve our resources and protect the climate.

That is active environmental protection!

The advantages at a glance!

The advantages at a glance!

Regardless of whether you mould, press, drill or mill: With KMA ULTRAVENT® you will manage each waste air problem and stay free in your choice of the production method.

KMA exhaust air filtration systems have zero negative impact on processes taking place during production. Existing production plants are able to continue operation without modifying their original design and will in turn meet the requirements of the Bundes-Immissionsschutzgesetz (BImSchG).

KMA exhaust air filtration systems use the most advanced, most cost-effective method for waste air purification by combining the techniques of electrostatic precipitators with gas scrubbers. In comparison to conventional methods of post-combustion, energy costs are decreased by up to 80 percent.

KMA exhaust air filtration systems ensure compliance with the emission limit values according to the TA-Luft regulations and the VDI directives. KMA systems are oriented towards the high demands of the German legislation relating to workplace safety (BG) and Federal Immission Control Act (BlmSchG)

KMA exhaust air filtration systems are not vulnerable to thermal wear. More than 3,000 systems installed in numerous manufacturing works, and some with over 50,000 hours of operation, serve as evidence of this.

The high efficient automatic filter cleaning system cleans the modules in regular intervals, which ensures the durability of the filter modules and low maintenance operation.