Exhaust air filter systems for industrial frying & cooking

Clean Air. Save Energy.

During the industrial frying process normally occurs an exhaust air mixture of smoke and intensive odours. The KMA ULTRAVENT® Hybrid Filter is an energy-efficient alternative to afterburning systems. KMA ULTRAVENT® exhaust air filtration systems eliminate oil, grease and odours from the exhaust air and are used at all frying and cooking systems such as frying lines, belt grills, contact cooker or hot air tunnels etc.

Compared to conventional post-combustion systems the KMA ULTRAVENT® exhaust air filtration has a significantly lower energy consumption.

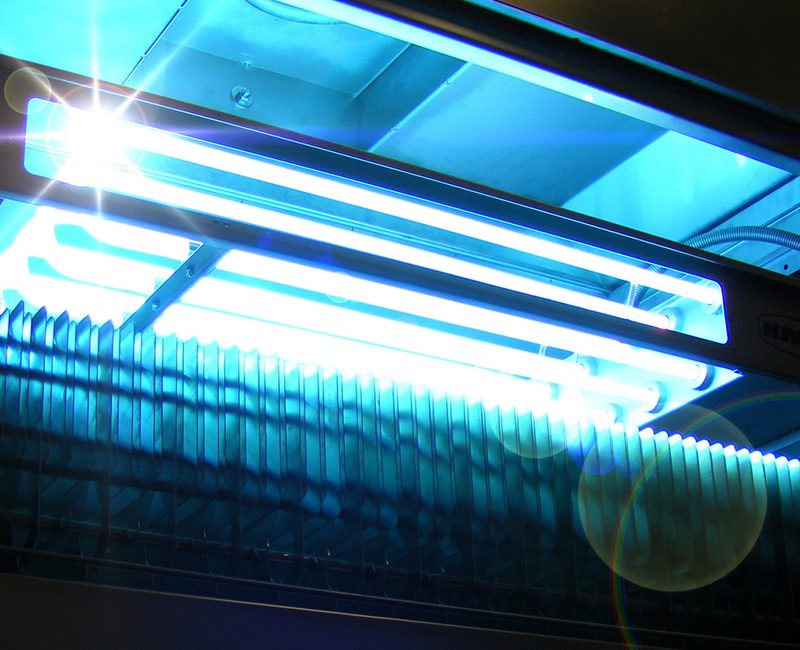

The exhaust air filtration takes place in two smart steps: first of all the exhaust air is conducted into an electrostatic precipitator which assures the highly effective separation of aerosol particles such as oil. The second step is an odour abatement through UV light.

And in case of significant heat energy in the exhaust air stream, KMA provides heat exchangers in order to transfer the recovered heat to another process – e. g. for heating of water.

The innovative exhaust air filtration system replaces conventional post-combustion systems and thus decreases the total energy consumption by up to 80%. This is an important improvement for the operational carbon footprint of manufacturing facilities for baking, frying and cooking.

The high eco-efficiency results from the interaction of various energy-efficient components:

- Energy-saving electrostatic filter

- UV-light for odour separation

- High efficient heat recovery system, consisting of heat exchangers and heating pump

Contact our expert in air filter systems for industrial frying and cooking

Ansgar Dobers

Please use the contact form above or give us a phone call on +49 2244 / 9248 42 or write us a mail to [email protected]

Download

Here you can download out latest product brochure:

Thanks to our energy efficient exhaust air filter system our clients have received numerous awards, positive press responses and even support by regional & national funding programs:

The outstanding alternative to post-combustion

Save up to 80% of your energy costs!

Less energy consumption means less costs. KMA filter system utilize the valuable heat out of the exhaust air and reduce the energy consumption of your production facilities by means of the integrated heat recovery system. How to minimise the energy costs of your industrial frying facilities is explained in the following case studies.

KMA ULTRAVENT® – modular and flexible

KMA ULTRAVENT® is a modular exhaust air filtration system, consisting of the following filter components:

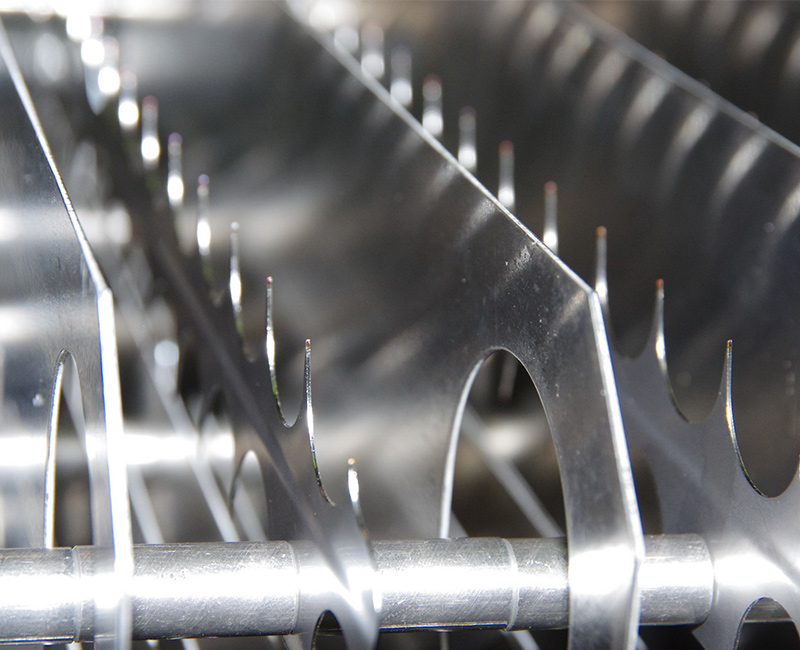

The ULTRAVENT® demister units consist of robust 50 mm thick stainless-steel mesh wire elements. This wire is held in position by expanded metal mesh, both on the incoming and outgoing side of the gas flow. The special shaping of the wire allows for a high separating capacity for aerosols, droplets, and mist. The units can be washed for cleaning. Changing the demister elements is not necessary.

ULTRAVENT® electrostatic filter cells assure the highly effective separation of smoke, dust, and fine mist. “Blue haze” caused by the use of release agents gets separated effectively as well. The filter cells are characterized by the particularly robust design: frame and carrying bars made of stainless steel, insulators in oil-resistant ceramics, optimized design for the separation of liquid or viscous substances. These features make sure that the electrostatic filter is an economical and durable filter medium for many applications. Unsuitable filter types can quickly plug and become ineffective, leading to excessive costs associated with filter replacement and disposal. However, electrostatic precipitators never obstruct the air flow through the exhaust system.

With UV light, many intensely smelling VOC molecules can be oxidized. The result is a significant improvement in odour. In many cases, bad smells are completely eliminated. UV light needs, just like activated carbon, a good pre-filtration of dust or smoke in order to achieve full and long-term effectiveness. A reaction section, following the UV-oxidation stage, is always required to complete the oxidation process.

During the purification of the waste air the integration of a heat exchanger ensures simultaneously the recovery of the process heat. At low waste air temperatures, the heat recovery can be optimized by combining the KMA Ambitherm high-efficiency heating pump. The recovered heat from the waste air can be used for heating the water or the building. As the heat exchanger is installed directly next to the filter zone, it can be cleaned automatically regularly together with the filter module.

Nearly all KMA ULTRAVENT® Filter systems offer the possibility of integrating an automatic filter cleaning system in the filter housing It is suitable for cleaning demister, electrostatic filters, UV-light oxidation and heat exchanger modules. The automatic filter cleaning system is unmatched in comfort and washing results due to the movable manifold, which moves back and forth over the filter modules during the cleaning process. This regular and work-saving cleaning of the filter cells ensures a minimal maintenance requirement. Its intelligent control reduces simultaneously the consumption of washing water and cleaning products.