Case study for frying lines and cooking ovens: The KMA ULTRAVENT® Hybrid Filter System

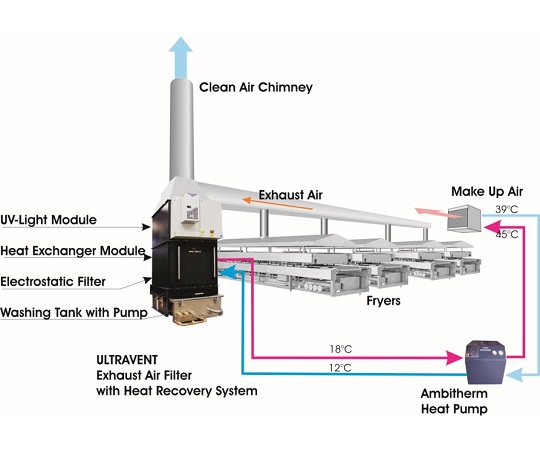

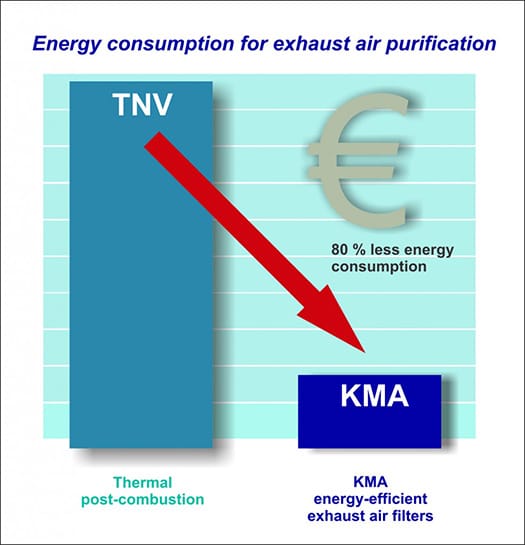

The ULTRAVENT® Hybrid filtration system with the highly efficient heat recovery system and UV light for odor removal is particularly suitable for the application of industrial frying lines. In this case, the KMA exhaust air filtration system is an energy efficient alternative to post-combustion systems.

How great the savings are illustrates the following case study example: A meat product manufacturer planned a large extension of his capacity of frying lines and cooking ovens. At the same time, the factory should produce more energy efficiently and fulfill the ecological objectives of the management.

The solution: With the extension of the capacity the company replaced its old post-combustion system with an exhaust air volume of 5000 m3/h by a KMA hybrid filter system with a capacity of 25000 m3/h.

While the old post-combustion system released every year more than 1000 tons of CO2, the CO2 emission of the new exhaust air filtration system was reduced to only about 115 tons despite the fivefold increase of the exhaust air capacity. Thus the company has reached its goal to reduce the „carbon footprint“ in a sustainable manner with one single renovation measure. The yearly savings of operating costs led to an amortization period of less than 2 years!

Contact our expert in air filter systems for ovens, industrial frying and boiling lines

Ansgar Dobers

Please use the contact form above or give us a phone call on +49 2244 / 9248 42 or write us a mail to [email protected]

Download

Here you can download the current product brochure: