Case study: Air filter & heat recovery textile industry

The exhaust air purification at stenter frames is particularly challenging, because the resulting exhaust air mixture includes a considerable amount of oil, fibre and possibly also wax particles and can be odor-intensive in certain cases. Depending on the location of use strict regulations and legal requirements exist concerning emission limit values at stenter frames.

Energy costs have a large portion of the production costs of the stenter frame

Stenter frames are widely used in the textile-finishing sector for heat treatment of woven and knitted fabrics. The textile is not only dried in the stenter frame, but also heat treated for fixing. The operating temperature is mostly around 200°C depending on the process. In addition to the use of electrical energy (e.g. for motors and ventilators) the stenter frame needs a high thermal input, produced by expensive gas and thermal oil heating.

An unsuitable filter cell would rapidly clog up by the exhaust air from stenter frames, which results in high follow-up and replacement costs. Moreover, the exhaust air from stenter frames contains valuable waste heat, which can be used for follow-on processes.

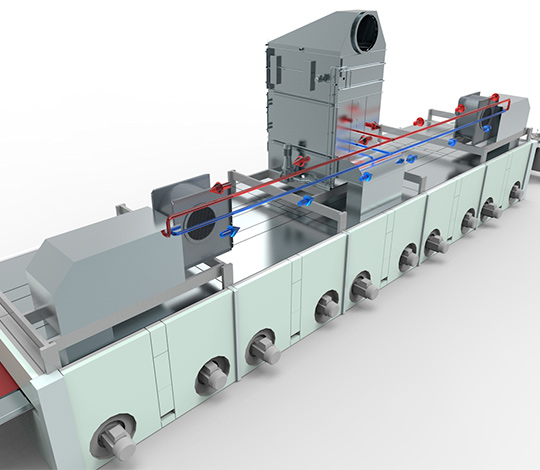

Case study – Heat recovery for the heating of air & water

Double heat recovery for double efficiency

Through the energy recovery of 720 kW per hour more than 72.000€ of annual energy costs could be saved. Furthermore, the CO2 emissions are reduced by more than 680 tons every year. With an amortization period of 2 years the following energy savings benefit the operating result.

- Reduced energy consumption of the stenter frame

- Heating of process water (e.g. for dye works)

Contact our expert in air filter systems for textile applications

Hannes Berteit

Please use the contact form above or give us a phone call on +49 2244 / 9248 42 or write us a mail to [email protected]

Downloads

Here you can download out latest product brochure:

Case Study – AUNDE

Heat recovery at the stenter frame for immense cost savings

Energy recovery saves the company 469kW per hour and thus 2,345,000 kWh of energy per year. This corresponds to a cost saving of more than 90,000€ per year. At the same time, annual CO2 emissions are reduced by 469 tons.

Case study – Heat recovery for heating air

Heat recovery for the supply air system of the stenter frame

Through the energy recovery of 287 kW per hour the CO2 emissions could be removed by more than 270 tons every year. With an amortization period of 4 years the following energy savings benefit the operating result of Freudenberg Performance Materials a leading global manufacturer of innovative technical textiles.

- Reduced energy consumption of the stenter frame and improved the carbon footprint

Case study – Heat recovery for the heating of water

Heat recovery for heating of process water

The company Kirayteks saves 300€ energy costs every day and more than 600 tons of CO2 emissions annualy due to the KMA filter systems. The cost advantage of the heat recovery leads to an amortization period of the new KMA exhaust air filtration system of less than 2 years.

- Reduced energy consumption due to integrated heating of process water (e.g. for dye-works)

Case Study – PASA

Textile company Pasa invests in exhaust air filtration system by KMA Umwelttechnik

Thanks to the filter systems, Pasa Tekstil can save 1,691,500 kWh per year. This enormous cost saving means that KMA’s systems pay for themselves in a very short time. In addition, the company saves more than 532 tons of CO2 per year, thus improving its carbon footprint.