Exhaust air purification and heat recovery in the vulcanization

Filter systems for rubber and rubber processing

Since its invention by Charles Goodyear in 1839, vulcanization has been the key process in the production of elastomeric plastics. The term is used for all processes by which rubber, rubber and other elastomers are brought from a state of predominantly plasticity to a state of predominantly high elasticity. Whether sulfur vulcanization or hot-air vulcanization – all vulcanization processes release heavy contaminants with the exhaust air and are faced with the challenging question of comprehensive, cost-effective and energy-efficient exhaust air purification. In addition to the high-grade separation of impurities such as particles or oily and pasty aerosols, this area of application focuses in particular on the separation of odours and the efficient recovery of thermal energy. As an expert for exhaust air purification with more than 60 years of experience in various industries, KMA Umwelttechnik is your reliable partner for a holistic exhaust air purification concept in rubber and plastics vulcanization.

High-grade exhaust air purification during vulcanization

As in other areas of plastics processing, large volumes of exhaust air are produced during the vulcanization process. In order to clean these extensively and in accordance with legal requirements, many companies rely on energy-intensive afterburning systems. A resource-saving alternative are the powerful exhaust air purification systems of KMA Umwelttechnik. Thanks to their modular design, these systems can be individually adapted to the application and customer requirements.

Depending on the exhaust air situation, either a tubular or a plate electrostatic precipitator is used, which comprehensively cleans the exhaust air from oily and pasty aerosols, vapors, particles and other contaminants. In addition, the KMA exhaust air purification system can be extended and customized by further components thanks to its modular design.

Usually, several vulcanization plants are put into operation at the same time, so that large amounts of heavily polluted exhaust air are released into the environment at different sources at regular intervals. This is where KMA relies on its precisely fitting collection hoods. These are mounted directly above the emission source and thus reliably capture the contaminated exhaust air before it can enter the working area of the employees. As an alternative, connecting pieces are used on the furnace.

Due to its powerful and application-oriented design, the KMA exhaust air purification system achieves a separation efficiency of up to 99 % depending on the application.

The KMA exhaust air purification system can be equipped with the automatic filter cleaning system (CIP). This fully automatic cleaning system reliably removes all filter residues without the need to change the filter medium. Furthermore, modules for heat recovery and odour separation can be combined.

Integrated heat recovery reduces operating costs

The vulcanization of rubber and plastics requires very high temperatures, usually between 120°C and 160°C. This process therefore has a high heat recovery potential. Especially in vulcanization processes such as hot air vulcanization, which are based on the circulating air principle, great cost savings can be realized by using innovative heat recovery systems.

Depending on the application and customer requirements, the heat recovery system consists of one or more heat exchangers which can be connected to the high-performance heat pump KMA Ambitherm® if required. The KMA heat recovery system is connected downstream of the KMA electrostatic precipitator module to allow for the recovery of thermal energy from the cleaned exhaust air stream to a high degree. This energy can then be fed back into the production cycle or used for subsequent processes or other applications. In this way, companies can easily and efficiently reduce operating costs and at the same time achieve a positive improvement in their own ecological balance.

Reduce odor emissions

In addition to heat recovery, the high-grade separation of odours is also available as a supplement to the exhaust air filters from KMA.

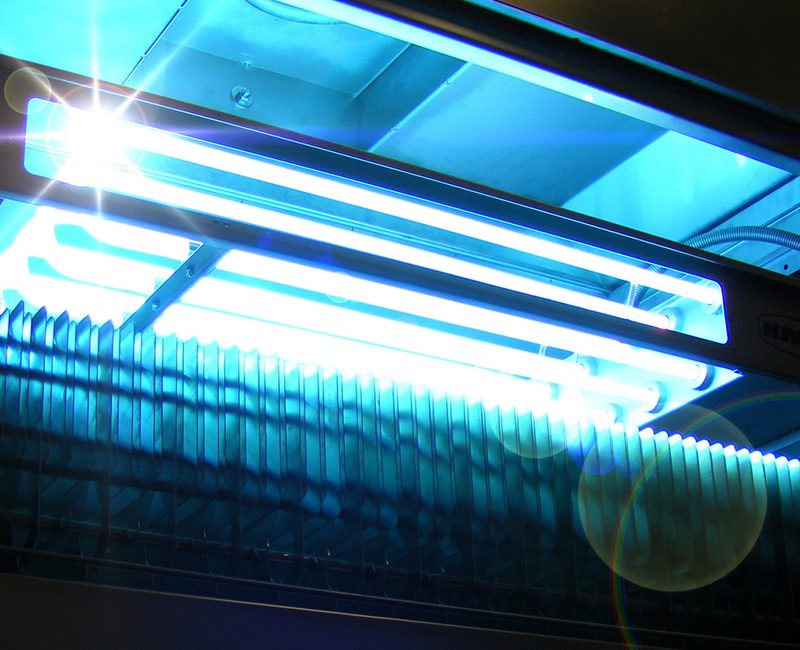

The high odor load of exhaust air confronts plastics processing distributors worldwide with the question of energy- and cost-efficient separation of these odors. KMA Umwelttechnik uses a UV light module for this purpose. This module reliably removes odorous molecules from the exhaust air stream. The number of UV-light modules is adjusted to the odour load. Depending on the application, these modules can also be combined with the KMA activated carbon filter.

KMA exhaust air purification plants are suitable for the following vulcanization processes, among others:

- Sulphur vulcanization,

- Salt bath vulcanization,

- Hot air vulcanization,

- EPDM vulcanization,

- Vulcanization of Polychlorbutadiene,

- Peroxide vulcanization and

- Vulcanization with high-energy radiation

Contact our expert for exhaust air purification and high-grade heat recovery during vulcanization

Hannes Berteit

Please use the contact form above or give us a phone call on +49 2244 / 9248 42 or write us a mail to [email protected]

Advantages of the KMA exhaust air purification concept:

- The innovative filter design guarantees high energy efficiency

- Automatic filter cleaning system (CIP) enables time and cost-saving cleaning

- Filtration without loss of performance as a cost-effective and energy-efficient alternative to conventional exhaust air purification systems

- Meets the requirements of current national and regional environmental protection regulations

- Modular design for individual combination with modules for odor separation and heat recovery

- High quality stainless steel construction for low material wear and long life. A costly exchange of filter elements is not necessary.

KMA ULTRAVENT® – modular und flexible

KMA ULTRAVENT® is a modular exhaust air purification system consisting of the following filter modules:

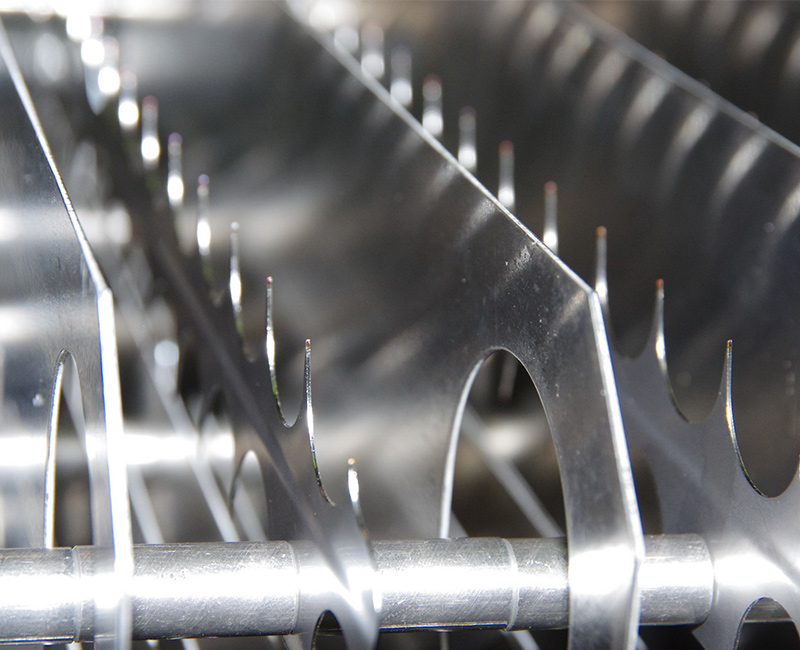

The KMA ULTRAVENT® demister cells consist of stable 50 mm thick stainless steel wire meshes, which are fixed on the inlet and outlet side by an expanded metal mesh. The special rolling of the wire enables high separation efficiency of aerosols, droplets and mists. The cells can be cleaned automatically. An exchange of the demister cells is not necessary.

The KMA electrostatic precipitator achieves a high degree of separation of finest particles, oily and pasty aerosols or vapours – without any sticking or pressure loss. Particles, aerosols and other contaminants in the exhaust air stream are electrostatically charged and deposited on the collector plates. The filter module is automatically cleaned at regular intervals. This eliminates the need for costly filter replacement. KMA electrostatic precipitators are characterized by their high efficiency and long service life.

The KMA modular filter system offers a wide range of mechanical filter cells for almost any application. The mechanical filter cells of KMA Umwelttechnik can be used as pre-filters (filter class G), as high-performance main filters (filter class F) and as HEPA filters (filter class H) with high separation efficiency.

For a time and energy efficient recovery of valuable process waste heat, KMA Umwelttechnik uses its integrated heat recovery system. This system consists of the effective KMA heat exchanger and – depending on the application and customer requirements – the powerful KMA Ambitherm® heat pump. The recovered heat can then be fed back into the product cycle and used for other purposes. The KMA heat recovery system is part of the KMA exhaust air purification system and is therefore also cleaned at regular intervals by the automatic filter cleaning system (CIP).

The innovative KMA UV light module is an elementary component of the separation of intensive odorous VOC molecules. This is done by photooxidation, which results in a significant improvement of the odour load. Depending on the odour load of the exhaust air stream, the KMA UV light module enables a complete odour separation.

For a complete separation the UV-light module, as well as the activated carbon filter, is installed downstream of the electrostatic precipitator. This ensures a comprehensive particle separation. After the UV-oxidation stage either a reaction line or catalytic carbon is required to break down the ozone.

In addition to the KMA UV light module, KMA also uses the KMA activated carbon filter for the separation of odorous vapors, mists or aerosols. Here, the odour-bearing molecules are deposited on the porous surface. The KMA activated carbon filter is installed downstream of the KMA electrostatic precipitator to achieve an optimal cleaning result.

For a comprehensive separation of odorous aerosols, gases, vapors or mist, KMA uses its innovative KMA exhaust gas scrubber. This works according to the absorption principle, with the help of a suitable washing liquid the impurities are bound and separated. Combined with the KMA electrostatic precipitator or the mechanical filter from KMA, the KMA exhaust gas scrubber achieves a high separation efficiency with a low water consumption.

The automatic KMA exhaust air purification system CIP (“cleaning in place”) is an elementary part of the KMA exhaust air purification concept for many applications. The cleaning of the filter cleaning system CIP does not only include the KMA Electrostatic Precipitator, but also attached filter components such as the KMA UV light module or the KMA heat exchanger.

The KMA filter cleaning system uses a movable nozzle block and thus guarantees an unmatched cleaning result. It can be programmed fully automatically and individually – for regular cleaning without high personnel expenditure. The intelligent control system ensures low consumption of washing water and cleaning agents. This greatly reduces the maintenance effort for the entire exhaust air cleaning system.