Comprehensive product range for modular air filter systems

Our modular conception

KMA exhaust air filtration systems are made up of several separate modules. With the basic housing there is a distinction between the KMA trademarks ULTRAVENT® and AAIRMAXX®.

KMA AAIRMAXX®

KMA AAIRMAXX® exhaust air filtration systems are mainly used in the food processing industry. AAIRMAXX® Systems are characterized by the die AAIRMAXX® ESP Electrostatic precipitator tube. Its design differs from the ULTRAVENT® Electrostatic filter cell and is particularly suitable for viscous emissions (e. g. tar-containing waste air from smokehouses). For lower exhaust air volumes AAIRMAXX® ESP Electrostatic filter tubes can be used also in the metal processing. They work on the principle of layer ventilation. KMA AAIRMAXX® exhaust air filtration system consists of electrostatic filter tube, gas scrubber and active carbon filter depending on the type of exhaust air.

KMA ULTRAVENT®

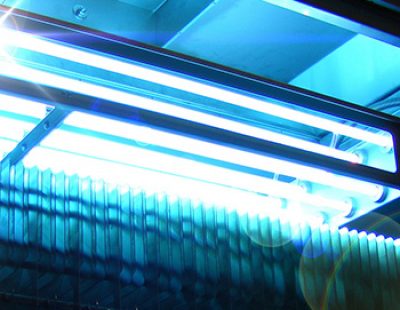

The energy saving KMA ULTRAVENT® exhaust air filtration system is often used in the metal processing industry. But it is also very suitable for roasting and frying machines. The ULTRAVENT® housing allows an exact adaptation to the needs due to the equipment with the necessary module units. Depending on the type of emission ULTRAVENT® can be equipped with demisters, electrostatic filter units, bag filters, activated carbon elements, or UV light tubes, the latter for the oxidation of odours. Retrofit kits for subsequent modifications are available as well. ULTRAVENT® exhaust air filtration system enables the purification of the hall air in energy saving recirculation mode depending on the area of application.

Clean air. Save energy.

On the way to perfection – optional additional equipment can facilitate and improve the operation of your plant

On the way to perfection – optional additional equipment can facilitate and improve the operation of your plant

KMA exhaust air filtration systems can be equipped with heat exchanger and KMA AMBITHERM® heating pump for energy efficient heat recovery. Industrial manufacturing processes cause often warm exhaust air. The AMBITHERM® heat pump connected to the filter system extracts the heat by means of the heat exchanger, which can be re-used for follow-up processes. Incoming fresh air, for example, can be heated energy-efficiently and extremely economically in this way.

Compared to traditional outdoor air heating pumps, AMBITHERM ® Exhaust Air Heating Pumps extract their energy even on cold winter days from the always relatively warm hall exhaust air. Simultaneously the heat carrier has to be heated only to a relatively low flow temperature. The consequence: an extremely economical operation.

The coefficient of performance (COP) is up to 5 (from 1 kW electrical power more than 5 kW thermal energy is recovered). Therewith, AMBITHERM systems are significantly more economical than comparable heating systems!

The automatic filter cleaning system is available for many types of filter systems. It is suitable for cleaning all washable filter media and ensures a minimal maintenance requirement. Its intelligent control reduces simultaneously the consumption of washing water and cleaning products.

KMA exhaust air filtration systems are equipped with either contactor control or PLC. In case of automatic cleaning systems or integration in central monitoring systems it is recommended using the PLC.

When using KMA exhaust air filtration systems at machines with fire potential, all KMA systems are optionally available with fire detectors and fire extinguishing system.

In the case of fire the system is flooded with extinguishing gas and further damages can be avoided.

Our engineers have thought of everything

KMA exhaust air filtration systems are suitable for machines of all types and sizes. KMA AAIRMAXX® and KMA ULTRAVENT® provide a solution for any waste air problem and you remain free to choose the production process.

KMA exhaust air filtration systems have zero negative impact on processes taking place during production. Existing production plants are able to continue operation without modifying their original design and will in turn meet the requirements of the governmental emissions laws.

The combined procedure of electrostatic filter and further modular elements of the KMA exhaust air filtration systems is the most modern and most economical method for exhaust air purification. Furthermore, KMA exhaust air filtration systems are characterized by an almost completely wear-free operation. Using high efficient and washable filter media avoids the expensive change of them and the regular automatic cleaning of the filter elements ensures minimal maintenance. As KMA filters consist of high-grade materials, they are extremely durable and robust.