High-grade exhaust air purification and odor separation in roasting plants

Filter and heat recovery systems for food roasting

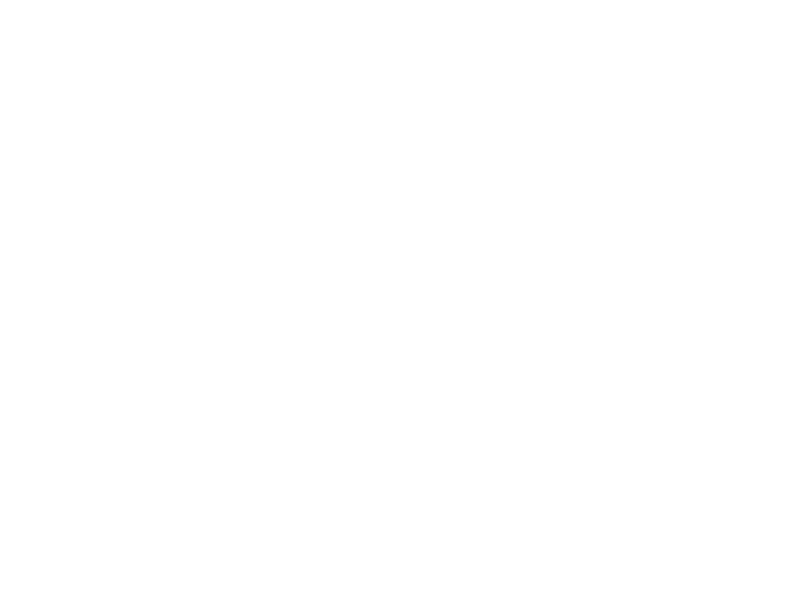

Whether for cocoa or nuts – roasting plants around the world face a special challenge. As achieving the desired aroma and the ideal degree of roasting is usually accompanied by high levels of exhaust air and odor pollution. These contaminants can be VOCs, odorous aerosols or other particles.

KMA exhaust air filtration systems are suitable for the following roasting processes, among others

- Cocoa roasting

- Roasting of nuts and seeds, e.g. peanuts or hazelnuts

- Roasting sunflower seeds or cashews

- Roasting of vegetables

- Grain roasting

Exhaust air filtration leads to energy and cost advantages

Conventional exhaust air purification processes such as catalytic thermal oxidation are often used for exhaust air purification in roasting plants. These systems achieves a high separation efficiency, but have a high consumption of fossil fuels. As a result, such systems are very cost-intensive on the one hand and have a negative impact on the life cycle assessment and the carbon footprint of the company on the other.

For this reason, roasting plants worldwide rely on efficient exhaust air purification systems from KMA Umwelttechnik. With the help of the highly efficient electrostatic precipitator module, KMA exhaust air filtration system achieve a separation efficiency of up to 99 % at low energy consumption.

Depending on the exhaust air situation, either a tubular or plate electrostatic precipitator is used, which cleans the exhaust air comprehensively from oily and pasty aerosols, vapors, particles and other impurities. Furthermore, thanks to their modular design, KMA exhaust air purification systems can be easily expanded and customized using additional components.

Comprehensive odor separation for a fine aroma

In addition to the exhaust air pollution by particles, aerosols and other solids or liquids, roasting plants are confronted with the strong odor pollution of the exhaust air. Due to their frequent proximity to residential areas or city centers, roasting plants have to also meet separate regional and national legal requirements with regard to exhaust air purification. Therefore, a comprehensive odor removal is an absolutely essential part of exhaust air purification.

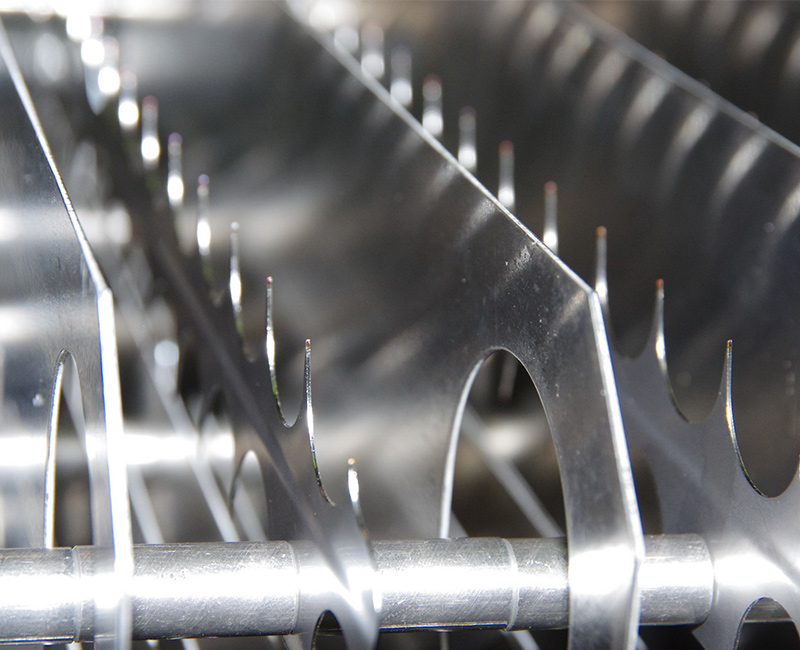

Therefore, KMA Umwelttechnik extends its exhaust air purification systems with powerful UV light modules. These systems reliably remove up to 90% of odors bound in the exhaust air stream. Thus, KMA exhaust air filtration systems achieve the specified clean air values. Depending on the present exhaust air situation, one or more UV light modules can be connected upstream or downstream of the electrostatic precipitator module. Furthermore, KMA exhaust air purification systems can be combined with an activated carbon filter for additional odor separation.

Efficient heat recovery

For increased energy efficiency, KMA combines its exhaust air purification systems with efficient modules for heat recovery, consisting of heat exchanger and thermal heat pump.

The exhaust air first flows through the electrostatic precipitator and the various modules for odor separation. Afterwards the exhaust air flow is transferred into the KMA heat exchanger. If required, the heat exchanger can be additionally extended through the innovative KMA Ambitherm® thermal heat pump. In this way, KMA achieves enormous heat recovery rates, which result in the systems paying for themselves within a very short time period. The recovered thermal energy can then be fed back into the production cycle or be used for other applications.

Depending on the application and customer requirements, the purified exhaust air can then be transferred outside in air extraction mode, or returned to the production halls in energy-efficient air recirculation mode.

Conatct our expert for exhaust air purification and heat recovery in roasting plants

Ansgar Dobers

Please use the contact form above or give us a phone call on +49 2244 / 9248 42 or write us a mail to [email protected]

Download

Here you can download the current product brochure:

Our latest article on “Sustainable exhaust air technology in cocoa roasting” can be found here:

Selected references from the chocolate industry

Advantages of the KMA exhaust air purification system:

- High energy efficiency through reduced pressure loss of the filter medium

- Automatic filter cleaning system (CIP): time-efficient and hygienic cleaning for increased plant utilization

- Automatic discharge of the separated impurities

- Optional combination with systems for odor separation and heat recovery

- Meets the current national and regional environmental regulations.

- Durable stainless steel construction: hygienic with low wear — no need to replace filter elements

- High-performance filtration as an efficient alternative to thermal oxidation

KMA ULTRAVENT® – modular and flexible

KMA ULTRAVENT® is a modular exhaust air purification system consisting of the following filter modules:

KMA ULTRAVENT® demister units consist of robust 50 mm thick stainless steel mesh wire elements. This wire is held in position by expanded metal mesh, both on the incoming and outgoing side of the gas flow. The special rolling of the wire allows for a high separating capacity of aerosols, droplets and mist. The cells are cleaned by the automatic filter cleaning system (CIP). The demister cells do not need to be replaced.

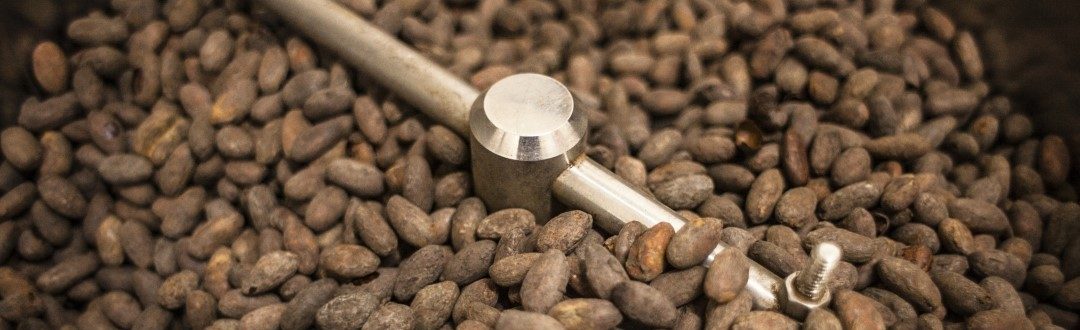

The KMA electrostatic precipitator achieves a high degree of separation of finest particles, oily and pasty aerosols or vapors — without experiencing any clogging or pressure loss. Particles, aerosols and other impurities in the exhaust air stream are electrostatically charged and deposited on the collector plates. The filter module is automatically cleaned at regular intervals. This eliminates the need for costly filter replacements. Electrostatic precipitators by KMA are characterized by their great cost efficiency and long service life.

The recovery of process heat can be carried out simultaneously to the purification of exhaust air using a suitable heat recovery system. At low exhaust air temperatures, heat recovery can be optimized by a combination of KMA heat exchanger and KMA Ambitherm® high-efficiency thermal heat pump. The heat recovered from the exhaust air is available for subsequent processes or for heating the building, for example. Since the heat exchanger is installed directly next to the filtration zone, it can be automatically cleaned regularly together with the filter module.

With the help of the KMA UV light module, many intensely smelling VOC molecules can be oxidized and separated. The result is a significant improvement in the odor situation, in many cases odors are completely eliminated. The KMA UV light module, as well as the KMA activated carbon filter, requires a comprehensive pre-separation of solid particles by the KMA electrostatic precipitator. After the UV oxidation stage, either a reaction line or catalyst coal is required to break down the ozone.

Activated coke is highly effective in absorbing many odors and vapors. Therefore it is used in food production as a universal agent for odour elimination. The odorous substances and air molecules accumulate on the surface of the activated coke and are thus removed from the exhaust air. For economical operation, a good pre-treatment of the exhaust air is always necessary, since impurities by particles or aerosols must be separated before the exhaust air enters the activated carbon filter.

For a reliable separation of odorous aerosols, vapors or gases, KMA uses the KMA exhaust gas scrubber based on the absorption principle. By using a suitable scrubbing liquid, these contaminants are bound and separated from the exhaust air stream. By using the upstream electrostatic precipitator, the KMA exhaust gas scrubber achieves a high separation efficiency at low water consumption.

KMA exhaust air filter systems can be equipped with an automatic filter cleaning system (CIP – cleaning in place). It is suitable for the cleaning of demisters, electrostatic filters, UV light and heat exchangers.

The automatic cleaning system convinces with its movable nozzle block, which is moved back and forth over the filter modules during the washing process, and is therefore unrivalled in terms of comfort and washing results. It enables regular, fully automatic and individually programmable cleaning of the filter cells. Thus, the automatic filter cleaning system minimizes the maintenance effort. The intelligent control of the cleaning process simultaneously reduces the consumption of washing water and detergent.