Sanitary dust filtration, product & heat recovery for spray dryers

Highly efficient product recovery of powder during spray drying

Spray dryers or flash dryers in the food, dairy and pharmaceutical industry need highly efficient dust filters in order to prevent fine dust particles escaping to the outside and to minimize the emissions. Mechanical filter such as bag filter or cassette filter are not a valid solution since they clough easily due to the fine dust particles. In addition, the baghouse need to be changed frequently for sanitary reasons.

The electrostatic KMA AAIRMAXX® is a highly effective and cost-saving alternative to bag filters. The spray drying process creates fine dust particles which can be filtered and recuperated thanks to sanitary product recovery. As a result, the energy efficient air filter system, the economic product recovery and the powerful heat recovery save operating costs and lead to a short payback period. The dedusting of the spray dryer for product recovery is suitable for the following areas:

- Pharmaceutical products

- Various foods

- Dairy products such as milk powder

- Protein powder

- Ground coffee

- Cocoa powder

- Malt powder

- Fish powder

- Yeast powder

- Fragrances and flavorings

The procedure is as follows:

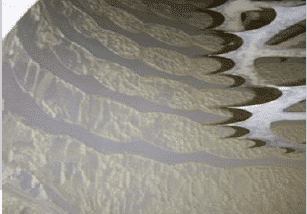

The exhaust air coming from the spray dryer or flash dryer and the cyclone(s) enters into the AAIRMAXX® filter at the bottom. The filter is made of a group of stainless steel tubes. The number of tubes depends on the required exhaust air capacity.

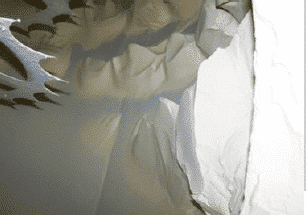

In the centre of each tube there is a stainless-steel laser cut ionization electrode. During the operation of the filter it creates a powerful electrostatic field, making the dust in the airstream move to the walls of the tubes. Hence the inside walls of the tubes act as a dust-collector. Due to the automatic filter cleaning system a fast and sanitary product change is possible.

Contact our expert in air filter systems for spray dryers

Ansgar Dobers

Please use the contact form above or give us a phone call on +49 2244 / 9248 42 or write us a mail to [email protected]

Download

Here you can download our latest product brochure:

Selected references from the food industry

Product advantages KMA AAIRMAXX®:

- Sanitary dust filtration ensures product (powder) recovery and hence increases plant yield

- CIP (cleaning-in-place) system for quick and sanitary filter cleaning enabling quick product changes and increased equipment capacity

- The open tubular design prevents clogging of the filter device

- Automatic dust discharge system

- Compliancy with common environmental regulations

- Optional heat recovery available

- Full stainless steel construction assures low wear and long lifetime – no filter exchange necessary

Lower energy costs + effective product recovery

Short downtimes. Quick and effective cleaning system.

Product changes in the spray dryer and frequent cleaning of the system for sanitary reasons need a quick and efficient cleaning system.

KMA AAIRMAXX® has a unique CIP-system which has been designed in co-operation with leading European food processing companies in accordance with highest sanitary standards. The walls of the collector tubes are equipped with a number of jets for highly efficient filter cleaning.

The jets are made in special sanitary design and ensure a quick and thorough cleaning of all parts of the collectors and the centre electrodes. The optimised and echelon formed configuration of the jets prevents the creation of spray shadows. The CIP-system is designed as an automatic operation without need of manual cleaning time. Water feed is usually supplied by the central washing system of the spray dryer unit. The rinsing process with brine and acid requires only a couple of minutes. Furthermore, the subsequent drying process needs only a little time, as the only parts that need to dry are metal walls of the tube. In this way, even multiple product changes per day are possible.

Effective product recovery – dedusting the spray dryer

Before knocking off dust

After knocking off dust

During the extraction air mode of the spray drayer, there is a powerful electrostatic field which makes the dust in the airstream move to the walls of the tubes. Hence the inside walls of the AAIRMAXX ® tubes act as a dust-collectors.

For frequent removal of the dust, each tube is equipped with pneumatic impactors. The dust flows down from the walls into the hopper underneath the tubes and passes a discharge airlock. The recovered dust flows to the central dust discharge and collector system.

The efficient recovery of powder dust, such as milk powder, protein powder or ground coffee powder is an essential cost advantage and reduces the payback period drastically.

Heat recovery for spray dryers

In times of energy shortage and rising energy prices, the effective heat recovery is an issue of increasing importance in the planning and operation of technical equipment. The exhaust air still contains a very high temperature level, especially during the spray drying process. In a system with integrated energy recovery, the heat gets transferred to the supply air of the spray drying process by means of a hydraulic circuit system. This is achieved with two independent multi-plate heat exchangers in the exhaust and supply air current. In this way, the air is filtered in an energy efficient way while saving a lot of energy costs during the spray drying process. To increase the energy efficiency of the system, it can be enhanced when combined with an Ambitherm® Heat Pump.

Upgrade your existent system. Save costs on a sustained basis.

KMA AAIRMAXX® filters can be used for replacing bag filters or scrubber in spray drying or as a final filter behind a cyclone in order to retrofit and upgrade an existing spray dryer plant. The replacement offers impressive benefits and a short amortisation period due to extra plant yield, caused by product recovery, reduction of energy costs and lower cleaning downtimes.

Consequently KMA AAIRMAXX® filters increase the efficiency and allow for a short payback period due to:

- reduced energy costs

- shorter setup and downtime periods

- improved product recovery