Energy efficient air filter systems for industrial applications

KMA offers tailor-made solutions relating to exhaust air purification, exhaust air filtration and heat recovery for your industry sector.

KMA products for the industry

Choose the modules of the exhaust air filtration system according to your needs.

Die casting, food processing, textile and rubber industry

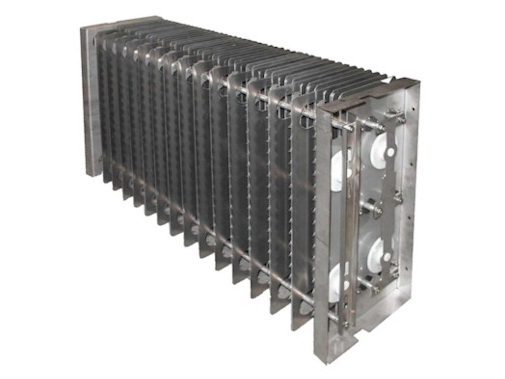

Our electrostatic filter cells achieve a high-grade separation of smoke, dust, fine mist and also sticky or greasy aerosols – for optimal clean air quality.

The energy consumption of our electrostatic filter cells for an exhaust air volume of 5.000 m3/h meets the energy consumption of a 100 W light bulb.

The expert in food processing exhaust air treatment.

Our AAIRMAXX® electrostatic tube filters are highly effective in separating coarse and fine particles, solid substances and liquid droplets from the air. AAIRMAXX® electrostatic tube filters are often used for exhaust air with higher concentrations of emissions like in smoke houses for examples. For difficult odour problems the energy efficient AAIRMAXX® electrostatic filter tubes can be combined with KMA scrubbers or activated carbon filters.

The automatic filter cleaning system (CIP) – Unmatched due comfort and washing result.

Our unique filter cleaning system operates fully automatic – programmable by remote control or default setting. Constant filter module performance without long machine idle times, cumbersome manual filter cleaning or repetitive filter replacement.

Integrated heat recovery system for increased energy efficiency.

The integration of a heat exchanger enables the recuperation of process heat derived from the hot exhaust air. The recuperated heat is then utilized for the heating of supply air, water or the heating of the production facilities. In the case of low exhaust air temperatures the heat recovery can be optimised by means of an additional KMA Ambitherm® high efficiency heat pump.

Industry case studies