Pure air in extrusion

Custom-made exhaust air solutions for extruders

Numerous products for industry and consumers are manufactured using extruders. In addition to plastics, rubber or aluminum, clays, ceramic masses or even dough-shaped food products are brought to their final form using extrusion.

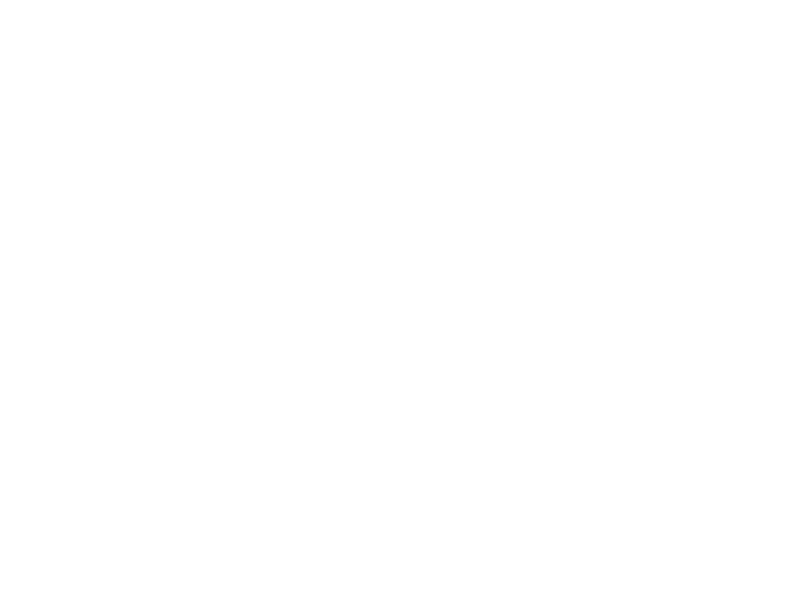

Through precisely controlled heat the raw material is transformed into a tough, malleable mass. Under adapted pressure, this mass is then pressed through a molding opening. It results in a long product strand with uniform dimensions and surface, which is then further processed into the final product. Depending on the final product or base material, the production line may include a calibration table, outlet, cutting unit and collection table.

Although extrusion is an efficient process for producing uniform and high quality products, it also requires a lot of energy which results in a high pollution of production exhaust air.

Custom-made exhaust air purification by KMA

However, how can efficient exhaust air purification at extruders be designed efficiently? Frequently used conventional exhaust air purification processes, such as thermal oxidation or wet scrubbers, achieve high separation values, but are very cost-intensive due to their own high energy consumption which poses a negative effect on the company’s life cycle assessment (LCA).

Energy-efficient and cost-conscious alternatives are theexhaust air purification systems by KMA Umwelttechnik. With its core piece, the innovative KMA electrostatic precipitator, KMA exhaust air filtration system achieve a separation efficiency of up to 99 %. The energy consumption of the KMA electrostatic precipitator is far below that of a thermal oxidation system.

High-grade odor separation with KMA

The processing of plastics, rubber, caoutchouc or other odor-intensive materials results in the exhaust air being highly polluted by odors. Especially during the extrusion of plastics the exhaust air is intensively contaminated by vapors, oil and emulsion mists as well as plasticizer fumes or smoke. In the worst case, these contaminations can have adverse health effects on personnel or negative impacts on the environment. Therefore a comprehensive separation according to legal regulations is of utmost importance.

The KMA electrostatic precipitator does not only remove reliably particles, vapors, oil or emulsion mist and aerosols from the exhaust air, but — when combined with the powerful KMA UV light module and KMA activated charcoal filter — also odors and harmful plasticizer fumes. Thus, KMA exhaust air purification systems enable clean air quality in accordance with the applicable national and regional legal regulations.

Intelligent heat recovery reduces operating costs

The extrusion of plastics, aluminum or other thermoplastic base materials requires large amounts of thermal energy; a valuable resource that is often released into the environment — unused, untreated and without the possibility of an efficient heat recovery. This is not only cost-intensive and less energy-efficient for companies, but also has a negative impact on their life cycle assessment (LCA). In order to counteract this negativ impact, KMA Umwelttechnik relies on its innovative heat recovery systems. Thereby a combination of heat exchangers and if necessary thermal heat pumps is adapted individually to the customer’s needs and requirements.

Powerful exhaust air purification for various products:

The KMA exhaust air filter systems can be used for extrusion processes of the following products, among others:

- Pipes

- Treads

- Plates

- Foils

Our expert for exhaust air purification and high-grade odor removal in the extrusion

Hannes Berteit

Please use the contact form above or give us a phone call on +49 2244 / 9248 42 or write us a mail to [email protected]

Advantages of the KMA exhaust air purification concept:

- High energy efficiency thanks to innovative filter design

- Automatic filter cleaning system (CIP) for adapted and effective cleaning of the filtration modules

- High-performance filtration without any clogging or sticking as an efficient alternative to conventional exhaust air purification systems

- Meets the requirements of current national and regional environmental protection regulations

- Individual extensions for odor separation and heat recovery are available

- Durable stainless steel construction: hygienic with low wear — no need to replace filter elements

KMA ULTRAVENT® – modular und flexible

KMA ULTRAVENT® is a modular exhaust air purification system consisting of the following filter modules:

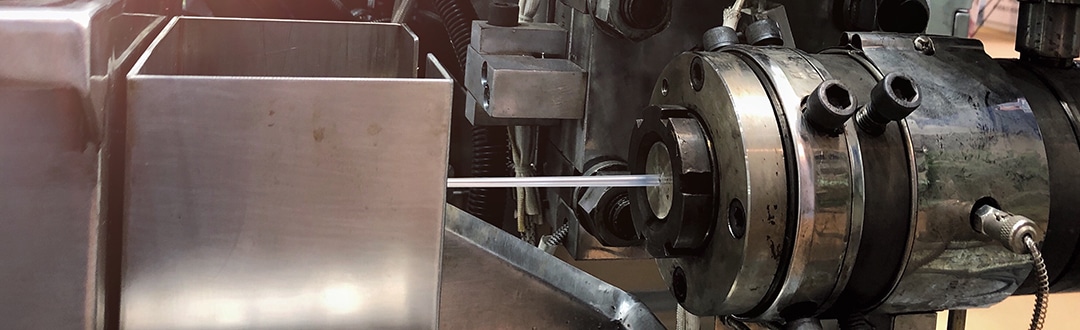

The KMA ULTRAVENT® demister cells consist of stable 50 mm thick stainless steel wire meshes, which are fixed on the inlet and outlet side by an expanded metal mesh. The special rolling of the wire enables high separation efficiency of aerosols, droplets and mists. The cells can be cleaned by washing them out. An exchange of the demister cells is not necessary.

The KMA electrostatic precipitator achieves a high degree of separation of finest particles, oily and pasty aerosols or vapours – without any sticking or pressure loss. Inside the filter there are numerous filter cells, each consisting of an ionizer and several collector plates. Particles, aerosols and other impurities in the exhaust air stream are electrostatically charged and deposited on the collector plates. The filter module is automatically cleaned at regular intervals. This eliminates the need for costly filter replacement. KMA electrostatic precipitators are characterized by their high efficiency and long service life.

The KMA modular filter system offers a wide range of mechanical filter cells for almost any application. The mechanical filter cells of KMA Umwelttechnik can be used as pre-filters (filter class G), as high-performance main filters (filter class F) and as HEPA filters (filter class H) with high separation efficiency.

For the recovery of valuable process waste heat, KMA Umwelttechnik relies on integrated heat recovery. For this purpose, efficient heat exchangers and – if required – the powerful Ambitherm® heat pump are used. The heat extracted from the exhaust air can then be used for subsequent processes or other applications. The heat recovery system is part of the KMA filter concept and is therefore regularly cleaned by the automatic filter cleaning system (CIP).

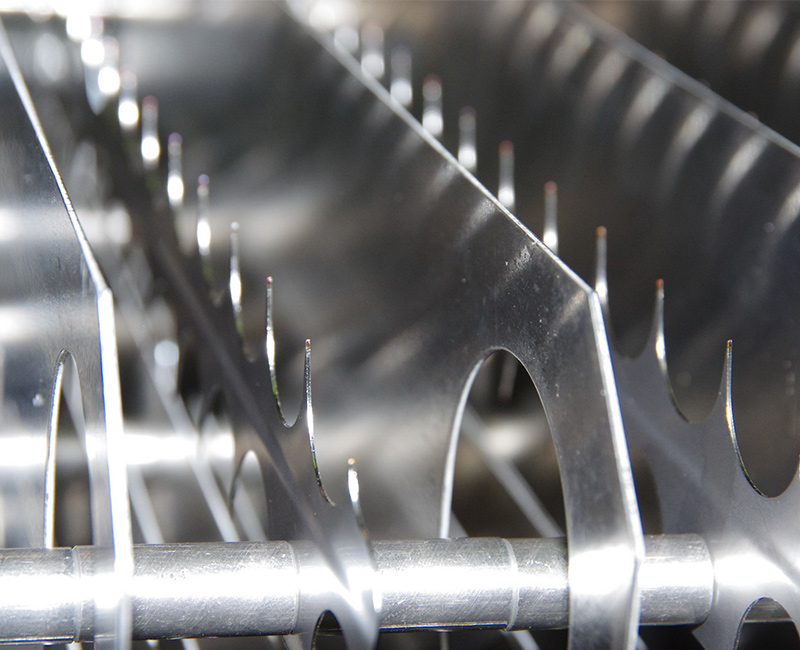

The powerful KMA UV light module helps to oxidize intensely smelling VOC molecules and to separate them from the exhaust air stream. This results in a clearly perceptible improvement of the odor load. Depending on the degree of pollution, the KMA UV light module achieves a complete separation of the odours.

For an optimal result, the KMA UV-light module, as well as the KMA activated carbon filter, is preceded by the KMA electrostatic precipitator for a comprehensive particle separation. In addition, the KMA UV light module is always followed by a reaction line for an optimal result.

KMA also uses activated carbon and activated coke for the separation of odours, vapours and mists. Odor-carrying molecules accumulate on the surface of the activated coke and are thus removed from the exhaust air flow. For an optimal result, the KMA activated carbon filter is preceded by the KMA electrostatic precipitator for particle separation.

For a reliable separation of odorous aerosols, vapors or gases, KMA uses the KMA exhaust gas scrubber based on the absorption principle. By using a suitable scrubbing liquid, these contaminants are bound and separated from the exhaust air stream. By using the KMA electrostatic filter or the mechanical filter from KMA, the KMA exhaust gas scrubber achieves a high separation efficiency at low water consumption.

For many applications, a KMA exhaust air purification system can be equipped with the automatic filter cleaning system (“cleaning in place”). The filter cleaning system CIP is also used for cleaning of attached filter components like the KMA UV light module or the KMA heat exchanger.

In order to ensure a high degree of cleaning, the filter cleaning system is equipped with a movable nozzle block. During the cleaning process, this nozzle block moves back and forth over the different filter modules, thus cleaning them comprehensively and reliably. The system can be individually programmed and thus cleans regularly and fully automatically – without a large number of personnel. In this way, the filter cleaning system reduces the maintenance effort of the exhaust air filter system. Intelligent control of the cleaning process also keeps the consumption of washing water and cleaning agents low.