Case study for industrial smokehouses: The KMA AAIRMAXX® Filter System

KMA exhaust air filtration systems reduce your operating costs

In our case study a well-known company produces meat and sausage products at 14 modern locations in Italy. The company offers a wide range of typical Italian meat products. The meat and sausage products are made of high-quality raw materials according to their own recipes. Quality has the highest priority. The quality awareness continues in the choice of the work equipment.

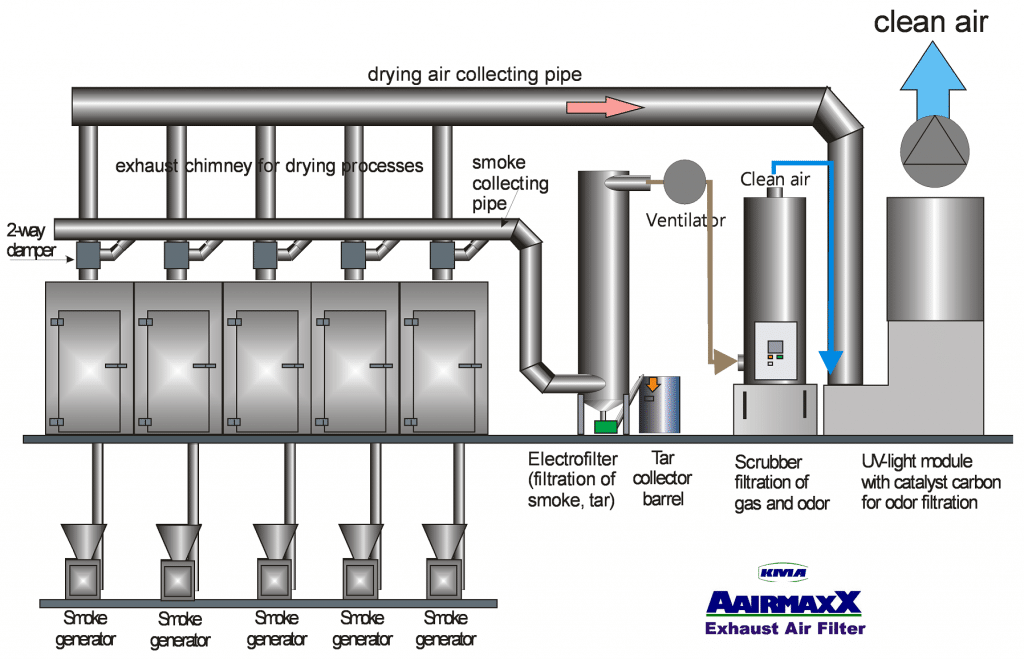

During a production expansion in 2016 the smokehouse was expanded by 4 hot smoke plants. Even before the production expansion the company used the KMA AAIRMAXX exhaust air filtration system, but for the new plant a larger KMA AAIRMAXX exhaust air filtration system for a higher total exhaust air volume of up to 2.250 m3/h was installed outdoors in a frost-resistant housing.

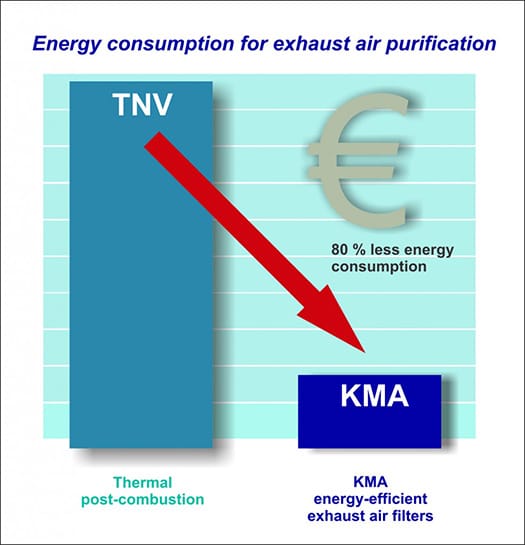

The KMA AAIRMAXX 2250 Filter System saves up to 85 % of the calculated annual operating costs of the post-combustion system (with heat recovery). The CO2 emission from the KMA filter system only amounts to about 11 tons per year – in comparison to 213 tons before.

By using innovative exhaust air filter systems, smokehouses can sustainably avoid environmental pollution through smoke and odours and at the same time make an important contribution to climate protection through minimal energy consumption.

The energy efficient alternative to the expensive conventional post-combustion process.

Contact our expert in air filter systems for smoke houses

Ansgar Dobers

Please use the contact form above or give us a phone call on +49 2244 / 9248 42 or write us a mail to [email protected]

Download

Here you can download the current product brochure: