Case study for rubber processing plants: The KMA ULTRAVENT® exhaust air filter system

The Gummiwerk KRAIBURG Elastik plans to expand its production capacity by building a new production hall in the close vicinity of a residential area. The new production plant will produce rubber mats which will be used, for example, as impact sound insulation or damping material. For this purpose, used tires are processed into rubber granulate, which is used to manufacture the rubber mats.

The aim of the company is a sustainable concept with regard to environmental protection, occupational health and safety and economic efficiency of the new production plant. The odor emissions caused by thermal decomposition during the production process are to be greatly reduced.

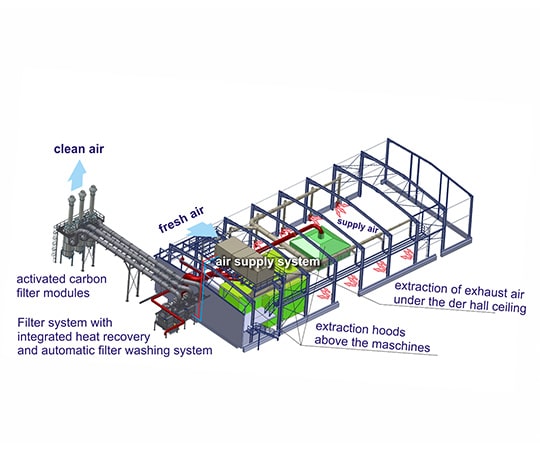

The solution: purification of the production exhaust air with a volume of 60.000 m3/h, while simultaneously using of the production waste heat.

A hybrid filter system consisting of electrostatic filter, heat exchanger and fine carbon filter removes the oily smoke, extracts the odors from the exhaust air and simultaneously removes the production waste heat. The exhaust air is used by the integrated heat recovery system to heat the production halls during the colder months. This fully covers the heat requirements of the production building.

The installation of the KMA ULTRAVENT® electrostatic filter system reduces CO2 emissions from production by 205 tons per year. In this way, the company goal of sustainably reducing the “carbon footprint” is achieved. The annual saving in operating costs leads to a payback period for the filter technology of approx. 3 years.

In addition to the selected industry examples, other areas of application can be supported

Download Brochure

Contact our expert in air filter systems for rubber processing

Hannes Berteit

Please use the contact form above or give us a phone call on +49 2244 / 9248 42 or write us a mail to [email protected]