Exhaust air purification and heat recovery at industrial baking lines

Save energy and CO2 with highly efficient exhaust air purification by KMA!

From bread and rolls to pizza dough and deep fried dough foods — producing baked goods requires individually adapted industrial production lines. In order to guarantee a high-quality baking result, the individual modules such as divider-rounder machine, proofing cabinet, cooling spiral or tunnel oven are fitted exactly to the respective baked goods.

However, the more production machines are adapted to the final product, the more complex is the resulting exhaust air. This is due to the various production steps leading to a highly variable contamination load of production exhaust air. In addition to the high particle and odor pollution, the contamination with oily and pasty aerosols poses a major problem for industrial bakeries, especially at production areas for deep-frying. If these impurities and odors are not removed from the exhaust air stream, they could build up on production machines, damaging them in the process, or enter the work area of employees.

KMA ULTRAVENT® — your powerful partner for pure air

Conventional exhaust air purification processes such as thermal or catalytic post-combustion achieve high separation values, but due to the high consumption of fossil fuels, these processes are very energy-intensive and thus have a negative impact on the carbon footprint and operating costs. Furthermore, these systems are very energy and therefore cost-intensive.

Therefore, the baking industry relies on the innovative KMA ULTRAVENT® from KMA Umwelttechnik for a comprehensive and energy-efficient exhaust air treatment. With its powerful electrostatic precipitator module, the KMA ULTRAVENT® separates up to 99 % of the impurities from the exhaust air flow. It uses electrostatic charging to remove the minuscule particles and finest liquid droplets from the exhaust air stream.

The innovative exhaust air filter system KMA ULTRAVENT® is available for exhaust air volumes of 5,000 to 30,000 m3 and can be seamlessly integrated into existing production plants. In addition to the electrostatic precipitator module, the KMA ULTRAVENT® can be combined with further components for odor separation and heat recovery.

High degree of odor separation

The odor of exhaust air is also one of the major challenges in industrial bakeries. Due to their frequent proximity to residential areas or city centers, such plants are often subject to special regional and national pure air quality regulations concerning the separation of odors from exhaust air. Therefore, high-grade odor separation is an important part of a high-performance exhaust air purification system.

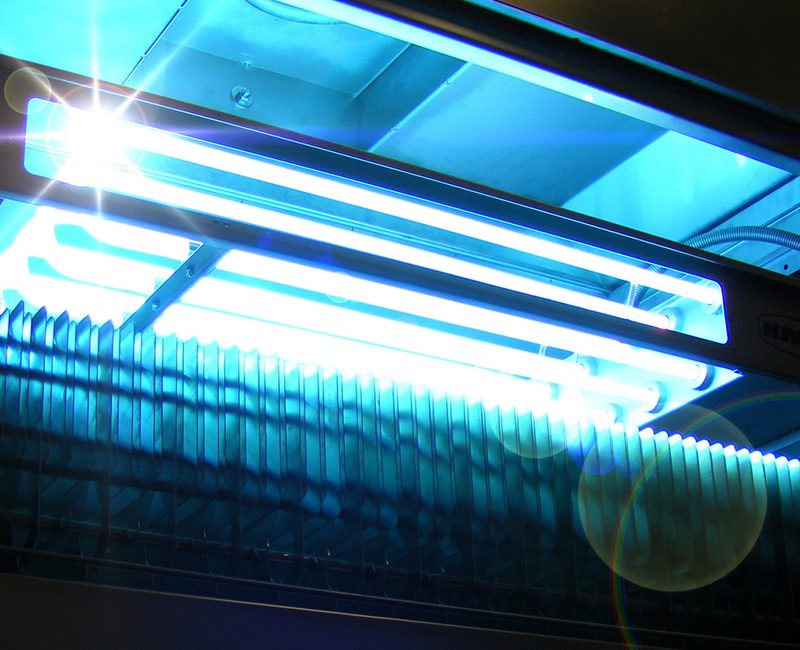

For this reason, KMA Umwelttechnik combines the KMA ULTRAVENT® — depending on the requirements — with a precisely fitted UV light module or an activated carbon filter. This way KMA UV light modules achieve deposition values of up to 90 % of odors. Thus, exhaust air purification systems from KMA Umwelttechnik meet the strict requirements for pure air quality.

Save energy and money with efficient heat recovery

In addition to exhaust air purification and comprehensive odor separation, KMA exhaust air filtration systems also offer the possibility of energy-efficient heat recovery. In industrial bakeries, the exhaust air flow often contains large amounts of thermal energy due to fermentation cabinets, ovens, boiling pans or cooling spirals and cooling cabinets. In most cases, this valuable resource remains unused.

To access this energy source, KMA combines its exhaust air purification system with powerful heat recovery systems consisting of a heat exchanger and, if required, the KMA Ambitherm® thermal heat pump. For efficient recuperation, the exhaust air flow first passes through the various modules for filtering and odor separation. Afterwards, the exhaust air flows through the KMA heat exchanger. For this purpose, KMA uses heat exchangers on air-air or air-water basis. This way, KMA achieves enormous heat recovery rates, which result in the systems paying for themselves within a very short time period.

The recovered thermal energy can then be fed back into the production cycle or be used for other applications. Depending on the application and customer requirements, the purified exhaust air can then be transferred outside in air extraction mode, or returned to the production halls in energy-efficient air recirculation mode.

Our expert for exhaust air purification and heat recovery on baking lines

Ansgar Dobers

Please use the contact form above or give us a phone call on +49 2244 / 9248 42 or write us a mail to [email protected]

Download

Here you can download the current product brochure:

Separate up to 90% odor emissions!

In the following case study you will find out how you can improve your production air in your baking line!

Advantages of the KMA ULTRAVENT ® exhaust air purification system:

- High energy efficiency through reduced pressure loss of the filter medium

- Automatic filter cleaning system (CIP): time-efficient and hygienic cleaning for increased plant utilization

- Automatic discharge of the separated impurities

- Optional combination with systems for odor separation and heat recovery

- Meets the current national and regional environmental regulations

- Durable stainless steel construction: hygienic with low wear – no need to replace filter elements

- High-performance filtration as an efficient alternative to thermal oxidation

KMA ULTRAVENT® – modular and flexible

KMA ULTRAVENT® is a modular exhaust air purification system consisting of the following filter modules:

KMA ULTRAVENT® demister units consist of robust 50 mm thick stainless steel mesh wire elements. This wire is held in position by expanded metal mesh, both on the incoming and outgoing side of the gas flow. The special rolling of the wire allows for a high separating capacity of aerosols, droplets and mist. The cells are cleaned by the automatic filter cleaning system (CIP). The demister cells do not need to be replaced.

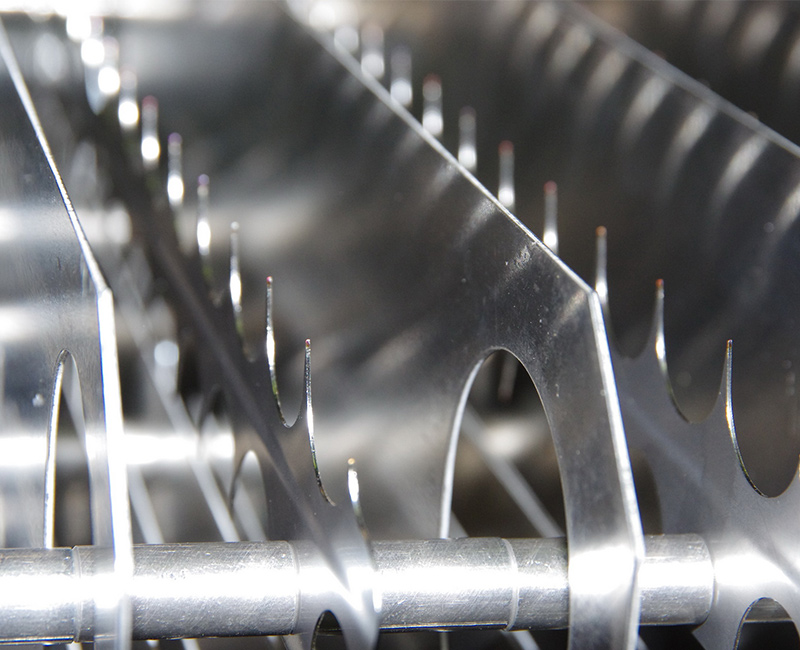

ULTRAVENT® electrostatic filter cells highly effectively separate smoke, dust and fine mists from the exhaust air stream. The electrostatic precipitator cells are characterized by their robust construction: Frames, electrodes and support rods made out of stainless steel, collectors either in aluminium or stainless steel, insulators in an oil-resistant ceramic design and a filter design optimized for the separation of liquid and viscous substances make the electrostatic precipitator an extremely economical and durable filter medium for numerous applications.

Unsuitable filter media can quickly become blocked by the greasy deposits and thus lead to high follow-up and replacement costs. KMA electrostatic precipitators, on the other hand, can absorb large quantities of grease on their metal collectors. The exhaust air can flow through the filter unhindered.

The recovery of process heat can be carried out simultaneously to the purification of exhaust air using a suitable heat recovery system. At low exhaust air temperatures, heat recovery can be optimized by a combination of KMA heat exchanger and KMA Ambitherm® high-efficiency thermal heat pump. The heat recovered from the exhaust air is available for subsequent processes or for heating the building, for example. Since the heat exchanger is installed directly next to the filtration zone, it can be automatically cleaned regularly together with the filter module.

With the help of the KMA UV light module, many intensely smelling VOC molecules can be oxidized and separated. The result is a significant improvement in the odor situation, in many cases odors are completely eliminated. The KMA UV light module, as well as the KMA activated carbon filter, requires a comprehensive pre-separation of solid particles by the KMA electrostatic precipitator. After the UV oxidation stage, either a reaction line or catalyst coal is required to break down the ozone.

Activated charcoal is highly effective in absorbing many odors and vapors. Therefore it is used in food production as a universal agent for odor elimination. The odorous substances and air molecules accumulate on the activated coke surface and are thus extracted from the exhaust air. For economical operation a good pre-treatment of the exhaust air is always necessary, as impurities by particles or aerosols have to be separated before the exhaust air enters the activated carbon filter.

For a reliable separation of osmophoric aerosols, vapors or gases, KMA uses the KMA exhaust gas scrubber based on the absorption principle. By using a suitable rinsing solution, these impurities are bound and separated from the exhaust air stream. By using the upstream electrostatic precipitator, the KMA exhaust gas scrubber achieves a high separation efficiency with low water consumption.

KMA exhaust air filter systems can be equipped with an automatic filter cleaning system (CIP – cleaning in place). It is suitable for the cleaning of demisters, electrostatic filters, UV light and heat exchangers.

The automatic cleaning system convinces with its movable nozzle block, which is moved back and forth over the filter modules during the washing process, and is therefore unrivalled in terms of comfort and washing results. It enables regular, fully automatic and individually programmable cleaning of the filter cells. Thus, the automatic filter cleaning system minimizes the maintenance effort. The intelligent control of the cleaning process simultaneously reduces the consumption of washing water and detergent.