Die casting machine

Die Casting Machine

Die casting machines, or casting machines, are used in metal processing to produce metal castings (such as structural components in the automotive industry, among others). This branch of metal processing is also called die casting.

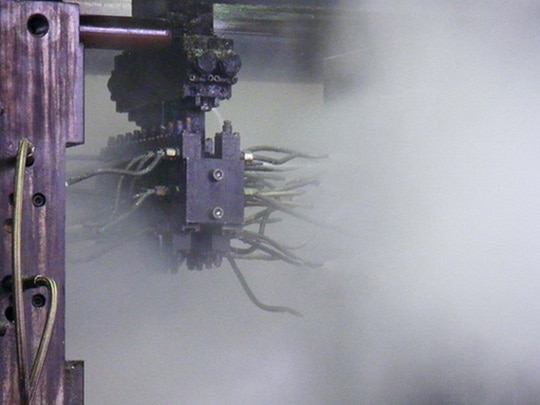

Die casting machines are an essential part of the effective series production of metal components. The process is based on the factors of speed and precision. For this purpose, the molten metal is first poured into a filling chamber with a casting piston. Under high pressure, this is then pressed into the die casting mold, where it cools. For easy removal of the finished casting after cooling, the die casting molds are sprayed with a release agent and greased if necessary. Due to the high temperatures of the liquid metal, the release agent evaporates or burns to a large extent. The resulting vapors and fumes contain harmful oily and pasty aerosols and impurities. To prevent this exhaust air from entering the working area of the personnel, leading companies in the die casting industry rely on the energy-efficient high-performance exhaust air filter systems from KMA Umwelttechnik.

The collection of these vapors is imperative for manufacturing and labor law reasons.

The die casting machines can be connected to a decentralized or central exhaust air filter system depending on the general conditions and customer requirements.

KMA exhaust air filter systems consist of an exhaust hood tailor-made for the die casting machine and an electrostatic precipitator module for the contaminated exhaust air. With the help of the extraction hood, the contaminated vapors are enclosed and directed to the filter module. The electrostatic precipitator cleans the exhaust air with a separation efficiency of up to 99%. On demand, the purified exhaust air passes through further filtration components, for example for heat recovery or odor separation.

Since high operating temperatures are reached in the die casting process, the use of heat recovery systems is particularly suitable at production sites with cold outside temperatures. Once the exhaust air stream has been comprehensively cleaned, it can either be transferred to the outside world in air extraction mode or returned to the production halls in energy-saving circulating air mode.

In addition, companies can realize even further cost savings with KMA exhaust air filter systems. As an expert for exhaust air purification and smoke extraction on die casting machines with more than 30 years of industry experience, KMA is a member of the working group for the definition of a uniform OPC UA interface. The OPC UA interface standard allows for a comprehensive data exchange between products of different manufacturers. The increased networking of the technologies integrated in the casting cell increases energy efficiency and occupational safety standards, among other things. By synchronizing the die casting machine and the exhaust air filter, the fan output of the filter system adapts to the spray cycle of the die casting machine. Such an efficiency measure enables energy savings at each individual casting cell and illustrates the advanced integration of the filter system into the die casting machine.

Related links

Related posts