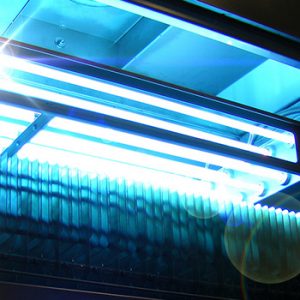

UV light module

UV light module

KMA UV light modules remove odors from exhaust air in food industries and other industrial areas with strong odor development. Odorous exhaust air contains a complex mixture of different oxygen and carbon compounds. UV light modules by KMA Umwelttechnik use UV rays of 185 nm and 254 nm to efficiently extract all odorous components. UV rays of 185 nm split atmospheric oxygen (O2) into individual free oxygen molecules (O). These oxygen molecules then combine to form ozone (O3) and oxygen-hydrogen radicals (OH). On the other hand, UV rays of 254 nm split long-chain carbon compounds, which cause odors in the exhaust air. In addition to UV rays, long-chain carbon compounds are also photochemically oxidized through ozone and OH radicals.

KMA UV light to eliminate odours

The extraction of long-chain osmophoric carbon compounds is an important part of exhaust air purification in food processing industries, in sewage treatment plants or in rubber processing, where odors are particularly intense. UV light modules by KMA Umwelttechnik are used to extract grease, solvents, VOC and various chemicals from the production exhaust air. To ensure an efficient exhaust air purification they use UV light radiation in the wavelengths 185 nm, the so-called vacuum UV radiation (VUV), and 254 nm, the so-called short-wave UV-C radiation (UVC).

The UV light module consists of numerous powerful UV light lamps. Depending on the individual circumstances, KMA UV light lamps can be installed as part of the electrostatic filter module or separately in a UV light tunnel. Due to their modular design, several UV light modules can be integrated into KMA exhaust air filtration systems. In order to fully oxidize all odor components, the UV light module is followed by pipelines forming a reaction line. At the end of this reaction line is a ventilator to prevent ozone from spreading inside the production hall.

To reduce odors up to 90%, KMA UV light modules are always combined with the energy-efficient KMA electrostatic precipitator. This guarantees a high degree of pre-separation of aerosols and solid particles. Furthermore, no plant-specific odors can be detected in process exhaust air after it has passed the exhaust air purification system. As a result of continuous use residues form on the UV light lamps, having negative and lasting effects on the functionality and performance of the entire module. The build-up can be removed using the automatic KMA filter cleaning system (CIP) or, in case of minor contamination, by hand. Regular cleaning avoids sooting and contributes to the longevity of the entire module.

Apart from industrial production plants, UV light modules are also used in the medical sector, e.g. in hospitals, surgeries and laboratories, as well as in agricultural animal husbandry or in air conditioning and water treatment systems for sterilization purposes. to ensure thorough sterilization, UV light modules in these areas are solely equipped with UV light lamps emitting 254 nm rays.

Related links

Related posts