Tube filter

Tube filter

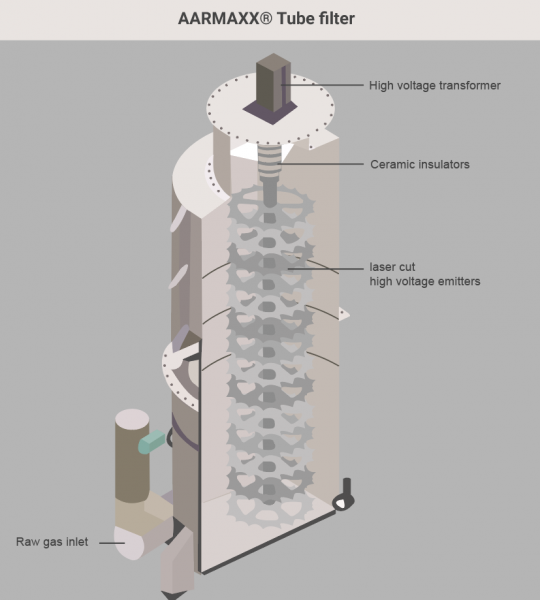

The electrostatic tube filter is the heart of the KMA AAIRMAXX® exhaust air filtration system. This filter module is adapted to the special exhaust air requirements of the food processing industry and is particularly suitable for viscous and highly concentrated emissions, such as the exhaust air generated in smokehouses. The tube filter can also be used to purify smaller exhaust air volumes in the metal processing industry. The hygienic stainless steel version is used in the spray drying process for the recovery of food processing powders, such as milk powder or pharmaceutical products.

Compared to the KMA ULTRAVENT® plate filter, the exhaust air flows vertically through the tube filter – without resistance or pressure loss. Inside the tube each filter cell contains an ionization electrode which generates a strong electric field on low energy input. Particles in the exhaust air stream such as dust, tar and water droplets are driven to the inner walls of the tube due to electrostatic forces and are either deposited there or flow downwards where they are collected in a separate container to be recycled or reused.

Collecting containers collect particles such as dust, tar and water drops.

Related links

Related posts

The tube is cleaned in regular intervals to keep the separation efficiency on a consistently high level. There are several proven methods of automatic filter cleaning for tube filters: dust and smoke deposits can be removed either by vibration, continuous rinsing of the walls, using steam or an integrated hot water pressure washing system. These properties make the KMA electrostatic precipitator an economical, low-maintenance and durable filter medium for various applications in industry.

The tube filter represents an energy-efficient and environmentally friendly alternative to conventional thermal oxidation systems. This method is frequently used in smokehouses and is operated at high temperatures of above 750°C in order to sufficiently separate emissions and odors from the exhaust air in accordance with legal requirements. However, using thermal oxidation achieves the goal of purified exhaust air only at expense of the environment: the supply of fossil fuels required to reach such high temperatures consumes immense natural resources, is cost-intensive and releases secondary emissions such as NO and CO2. The energy input of a KMA AAIRMAXX® exhaust air filtration system with a tube filter, on the other hand, requires only a few hundred watts per 1,000 m³ of smoking smoke. As a result, CO2 emissions can be reduced by up to 95 % compared to thermal oxidation systems.

The modular KMA AAIRMAXX® exhaust air filtration system can be combined with KMA gas scrubbers or activated carbon filters in case of strong odor problems.

Exhaust air filtration system as a container solution for outdoor installation next to the production hall of a smokehouse.