Plate filter

Plate filter

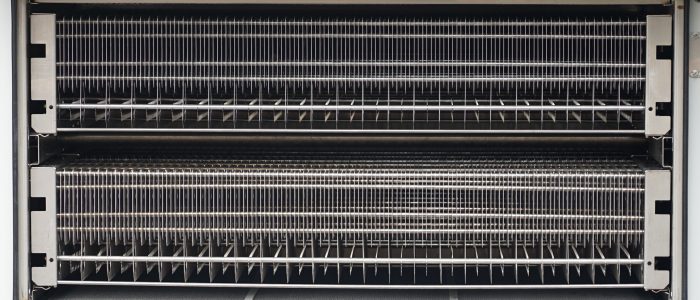

The electrostatic plate filter is the innovative heart of the KMA ULTRAVENT® exhaust air filtration system. The patented filter module has been specifically developed for the exhaust air requirements of the metal and textile processing industry and purifies the exhaust air in over 2,000 exhaust air filtration system worldwide reliably and to a high degree.

The core of the KMA plate filter is an ionization electrode. The ionizer generates a strong electric field while requiring only a very low energy input. When the contaminated exhaust air flows through the filter module, particles, dust or liquid droplets are driven to the collector plates of the electrostatic precipitator by the electrostatic charge of the filter. The residues are accumulate there or flow downwards into an external tank, where they can be collected, recycled or reused.

The KMA ULTRAVENT® plate filter is especially characterized by its constant separation efficiency of almost 100%. To maintain this standard, the filter module is cleaned regularly. Depending on requirements, the filtration module can be cleaned by vibration, steam or by using the automatic filter cleaning system (CIP), which uses washing water and cleaning agents.

For energy and exhaust air intensive industries, the KMA ULTRAVENT® plate filter is an energy-efficient alternative to conventional ventilation and filtration systems. The KMA ULTRAVENT® plate filter is a reliable partner for exhaust air purification all over the world – more than 2,000 plants worldwide ensure pure air quality in accordance with legal requirements and a positive ecological balance.

These properties make the KMA electrostatic precipitator an economical, low-maintenance and durable filter medium for various applications in industry.

Related links

Related posts